Trying to figure out the right decking board thickness for your new deck? Or maybe you’re putting new boards on an existing deck? Or even trying to determine joist spacing based on the type of decking you have chosen. Either way, this post should help you determine the optimal decking board dimensions for your project.

First, a few basics…

Experienced builders may want to skip this paragraph, but for most homeowners, it’s important to get your terminology right. Start with Joists… Joists are the heart of your deck infrastructure. If you have ever looked up at a deck from underneath, you’ve seen joists, which are dimensional lumber, (often 2×8’s or 2×10’s). They are set upright for strength, usually fastened to the house at one end, and sitting on top of a central support beam near the other end. Joists support the decking boards, which are fastened onto the joists from above. Joists are typically spaced out evenly for stability, ease of board installation and a clean look.

Joist spacing is the distance between each joist, and are measured in inches from center-of-joist to center-of-joist. Joist spacing is typically referred to as “On-Center” or “OC”, e.g, 16” OC. The bigger the space between the joists, the stronger you need your decking boards to be, as they will have bigger distances in between the support joists they are fastened to. Whether you are building a brand new deck, or putting new boards onto an existing frame, it’s critical to make sure you choose decking boards that are sufficiently strong to suit your joist spacing. Or vice-versa: make sure your joist spacing is properly aligned with the decking material you have chosen.

Getting Into Board Thickness…

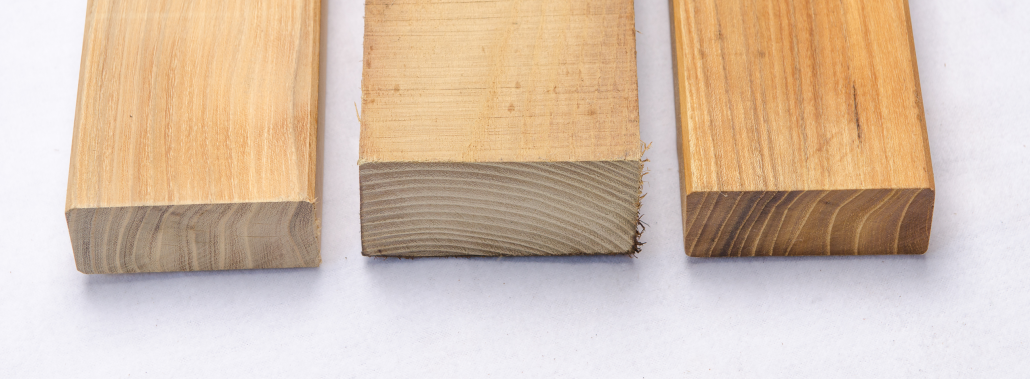

Decking boards come in varying thicknesses that can be a bit confusing. There is a nominal thickness and then an actual thickness. The most popular thickness for decking boards in North America is a 5/4 thickness which is an actual 1” thick. Use the table below to understand the most common board thicknesses:

Decking Thickness Definition Table

| Nominal Thickness | Actual Thickness | What You Need to Know |

| “Four-Quarter” or “1x” or “4/4”

E.g.1 x 4, 1 x 5, 1 x 6, 4/4 x 6 |

3/4” to 13/16” | This varies a bit for different wood products companies. Robi Decking’s nominal 4/4 or 1 x products are actually 13/16” thick for a bit of extra strength. |

| “Five-Quarter” or “5/4”

E.g., 5/4 x 6, 5/4 x 4 |

1” | This is the most common decking board sold; based on standard 16” OC joist spacing and type of material, this may be the minimum allowable thickness. |

| “Eight-Quarter” or “8/4” or “2x”

E.g., 2 x 6, 2 x 4 |

1.5” | These thicker boards are the strongest with minimal movement, and they can span the widest joist spacing. Often used on boardwalks. |

So what thickness of decking board to I need?

There are 2 factors that play into determining your required (or ideal) board thickness: Wood strength and joist spacing. Let’s start with strength. Different decking products and wood species have different strengths. Soft trees such as pressure treated pine and western red cedar are weaker woods. Composite decking products and thermally modified woods are extremely weak. Hardwoods such as Black Locust are extremely strong. The key metric used to measure the strength of decking is the Modulus of Rupture, frequently abbreviated as MOR. Sometimes referred to as bending strength, MOR is a measure of a product’s strength before it ruptures (breaks).

This brings us to the 2nd factor in determining your decking board thickness — joist spacing. The wider your joist spacing, the stronger decking board you need. Within a given wood species or decking product, the thicker the board, the stronger it becomes, relatively speaking. Conversely, the stronger your decking board, (based on MOR and thickness), the wider the joist spacing you can afford.

One of the most popular options for homeowners in the past 20 years has been composite decking, made of modified plastics and other materials. They made a splash in the market for their variety of colors and affordability, but over time the downsides have become more well-known. Today, many people are aware of the environmental hazards of using chemicals and plastics, as well as the heat absorption problem with composite decking — No bare feet allowed! But one of the lesser-known drawbacks is that they are very weak, and require joists to be placed very close together. If your joists are too far apart, the boards will bend as you walk over them. Over time, the boards can form “deck gullies” and in some cases crack or snap. The narrow joist spacing required by composite products increases the cost of your deck (more joists = more money) and also the time to install (more joists = more work).

At the other end of the spectrum are your temperate hardwoods, which are naturally strong, as measured by Modulus of Rupture. Boards made from these wood species are not only sustainable and long-lasting, they are also incredibly strong, and do not require joists to be spaced as closely together as composites or common soft woods like Pine and Western Red Cedar. So based on these factors (Strength, board thickness and joist spacing) here’s a table to determine your proper decking board sizes.

Comparison Table of Decking Board Strengths to Help Determine Thickness

| Decking Type | Actual Thickness (inches) | Modalus of Rupture (PSI) | Suggested On Center Joist Spacing (inches) |

| Black Locust 5/4 | 1” | 19,400 | 24” |

| Black Locust 1x | 13/16” | 19,400 | 16” |

| Tropical Hardwoods 5/4 | 1” | ~ 18,000 | 24” |

| Tropical Hardwoods 1x | 13/16” | ~ 18,000 | 16” |

| Thermally-Modified 5/4 | 1” | ~ 14,000 | 16” |

| Pressure Treated Pine 5/4 | 1” | ~ 12,500 | 16” |

| Western Red Cedar 5/4 | 1” | 7,500 | 16” |

| Composite 5/4 | 1” | ~ 3,000 | 12” |

Note: Most cities and counties have specific building code requirements for joist span, so be sure to check your local municipality website. Reputable deck builders will know the requirements already.

What’s the Impact on Cost?

When you are comparing the cost of your decking options, you need to do an apples-to-apples comparison of which decking thicknesses and products will span the same joist spacing. For example, if you are comparing Black Locust to a Composite Deck, you should compare the price of 1x Black Locust to 5/4 Composite and also factor in the extra work and cost to lay the extra joists.

Does Board Width Matter?

Many people think the selection of the width of the board is purely cosmetic or a function of price. However, the width of the board is crucial where dimensional stability is needed. The more narrow the decking board, the less it will move and the less it will cup. This is why in boat decking construction and flooring you will typically see a nominal 3 (actual 2.5”) or nominal 4 (actual 3.5”) wide deck board being used. In applications along the coast, over water, boardwalks over rivers, the narrower board will provide the needed dimensional stability. Where there is limited air flow under the deck or drainage issues, the narrower deck board can again prevent unwanted cupping and movement.

We hope this is helpful, and please feel free to share it on your social network of choice. In the meantime, to see how different wood materials compare on a number of dimensions, including durability and rot-resistance, Check out our Decking Comparison Chart.